Nanostructured fibers can impersonate human muscles

Mimicking the human entire body, especially the actuators that handle muscle mass motion, is of enormous fascination all over the globe. In recent years, it has led to many innovations to enhance robotics, prosthetic limbs and more, but building these actuators ordinarily requires complex procedures, with expensive and tricky-to-discover components.

Scientists at The College of Texas at Austin and Penn Point out University have developed a new kind of fiber that can perform like a muscle mass actuator, in numerous ways greater than other choices that exist right now. And, most importantly, these muscle-like fibers are easy to make and recycle. In a new paper posted in Mother nature Nano, the scientists confirmed that these fibers, which they originally found out when working on yet another task, are more productive, flexible and capable of tackling improved pressure in contrast to what’s out there now. These fibers could be employed in a selection of ways, such as medicine and robotics.

“You can mainly establish a limb from these fibers in a robot that responds to stimuli and returns electrical power, as a substitute of applying a mechanical motor to do this, and that’s good simply because then it will have a softer contact,” claimed Manish Kumar, an associate professor in the Cockrell Faculty of Engineering’s Section of Civil, Architectural and Environmental Engineering and one particular of the direct authors of the paper.

This variety of robotic arm could be employed in an assistive exoskeleton to assist individuals with weak arms regain movement and power. Yet another possible software, the scientists say, could be a type of “self-closing bandage” that could be used in surgical techniques and by natural means degrade inside the body the moment the wound heals.

“Actuators are any content that will transform or deform below any exterior stimuli, like pieces of a machine that will contract, bend, or extend,” stated Robert Hickey, assistant professor of elements science and engineering at Penn Condition and corresponding author on the paper. “And for systems like robotics, we want to acquire delicate, light-weight variations of these elements that can in essence act as artificial muscle mass. Our function is seriously about finding a new way to do this.”

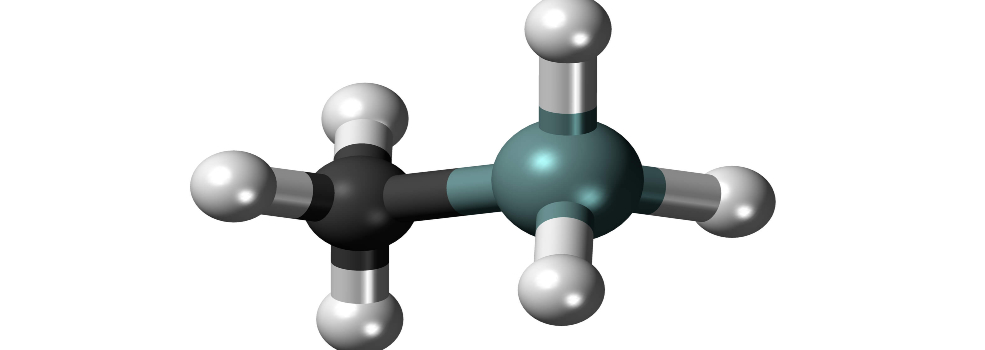

The fiber material is recognized as a block copolymer. Creating it only necessitates placing the polymer in a solvent and then introducing h2o. One particular component of the polymer is hydrophilic (captivated to h2o), while the other section is hydrophobic (resistant to drinking water). The hydrophobic areas of the polymer group jointly to protect themselves from the water, building the structure of the fiber.

Equivalent current fibers involve an electrical latest to promote the reactions that bond parts collectively. This chemical cross-linking is harder to make occur, when compared to the researchers’ new fiber, which is a mechanical reaction, meaning the parts acquire treatment of most of the function themselves. One more additional reward is it is simple to reverse the procedure and return the pieces of the fiber to their unique states.

“The simplicity of earning these fibers from the polymer and their recyclability are very vital, and it can be an factor that a great deal of the other difficult artificial muscle mass research won’t protect,” Kumar explained.

The researchers observed their fibers had been 75% a lot more economical in conditions of changing vitality to motion, able to manage 80% far more strain and could rotate with far more velocity and force than recent actuators. And it can stretch to extra than 900% of its length just before it breaks. The discovery arrived even though the scientists were functioning on anything else. They were making an attempt to use these polymers to make membranes for drinking water filtration. Having said that, the structures they manufactured ended up way too extended for membranes. They stretched out to 5 times their original duration and held that duration. The researchers found that these features were equivalent to muscle tissue, so they decided to shift the concentration.

The researchers are early on in the undertaking, and their upcoming approach is to understand a lot more about the structural alterations of the polymer and enhance some of the actuation qualities, which include electrical power density and speed. They also may perhaps use this similar layout technique to build actuators that respond to different stimuli, these kinds of as gentle.

Venkat Ganesan, a professor in the McKetta Section of Chemical Engineering and Rui Huang, professor in the Department of Aerospace Engineering and Engineering Mechanics, are the other Texas Engineers on the team. Also in the group from Penn State are Chao Lang, Elisabeth Lloyd, Kelly Matuszewski and Yifan Xu. The Air Drive Workplace of Scientific Analysis, Countrywide Science Foundation and Penn Condition funded the exploration.

Source: https://www.sciencedaily.com/releases/2022/06/220603153342.htm