LANXESS offers new natural preservative for energy-saving cold filling

- Range of microbiologically safe, energy- and resource-efficient cold filling products expanded

- LANXESS showcases Velcorin-related innovations and unveils the natural preservative Nagardo for the first time ever in the European Union

- New generation of dosing units offers a much greater degree of automation and digitalization

- New packaging for Velcorin replaces glass bottles

- LANXESS at Drinktec 2022 in Munich, September 12–16, Hall A5, Stand 437

At the world-leading Drinktec trade show in Munich from September 12 to 16, 2022, LANXESS will be unveiling its expanded portfolio for the microbiological protection of beverages. In addition to the tried-and-tested Velcorin technology, the completely natural preservative Nagardo was approved in July 2022 for EU-wide use in alcohol-free beverages.

Innovations for the existing Velcorin technology will also be presented, with the new generation of Velcorin DT Motion dosing units ensuring reliable, high-precision addition of the cold sterilization agent to the beverage. Also celebrating their premiere will be the new internally coated aluminum bottles specially developed for storing and transporting Velcorin and that will be used all over the world as break-proof and easily recyclable packaging in future. Thanks to a combination of this new packaging and ongoing developments in the production and quality process, the product shelf life has been increased by 50 percent to 18 months.

LANXESS offers the most effective natural preservative currently available on the market for alcohol-free beverages

“Registration in the EU allows us to continue expanding the global footprint of Nagardo. Alongside natural alternatives to artificial sweeteners and colorants, natural preservation is the missing piece in the puzzle for the beverage industry,” says Monika Ebener, Global Marketing Director for Natural Antimicrobials at LANXESS. Nagardo (the product name is derived from the words “natural guardian”) offers reliable, highly efficient preservation of the quality of beverages. The glycolipids, which are obtained from edible mushrooms native to the tropical rainforests of French Guiana, were discovered in a comprehensive screening process encompassing more than 100,000 natural substances. A dose that is as much as 50 times lower compared to commonly used synthetic preservatives is all that is needed. It is the most effective natural preservative currently available on the market for alcohol-free beverages.

“Even the design of our exhibition stand in Munich makes it clear that we have something really special to offer this year,” promises Janmarc Heitmann, who heads up the Beverage Technology business line in the Material Protection Products business unit at LANXESS. “We can not wait to welcome our visitors to the ‘jungle’ where the mushroom from which our natural preservative Nagardo is obtained actually grows.”

This “natural guardian” allows manufacturers to reshape their portfolio in line with changing consumer awareness and the demand for natural ingredients. A combination of Velcorin and Nagardo provides optimal protection for particularly sensitive beverages. “With our attractive portfolio, we want to participate in the global growth of the beverage market to an even greater degree in the future. Our two top brands Velcorin and Nagardo ensure that we are very well positioned to do so because we can cover virtually all beverage categories and trends,” says Heitmann.

The use of Nagardo and Velcorin can also help companies to achieve their sustainability targets, primarily by reducing energy consumption when switching from hot filling or tunnel pasteurization to cold filling using either one or the combination of both products. Consequently, PET bottles with lower wall thicknesses can be used compared to hot filling leading to less PET usage.

“We are not only offering a highly effective solution for the energy-saving cold sterilization of beverages, but also possess the expertise required to analyze production facilities and processes at a microbial level and highlight any optimization potential,” emphasizes Heitmann. In this context, the company runs two labs specialized in application technology and equipped with state-of-the-art chemical and microbiological analysis equipment. Support for small- and large-scale filling trials and assistance in regulatory matters round off the portfolio.

Ready for Industry 4.0

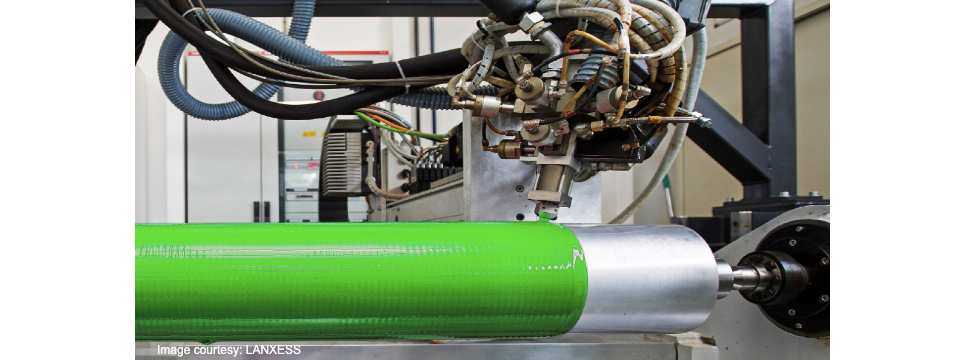

The new generation of dosing units is based on the tried-and-tested mechanical design of the Velcorin DT Touch series, albeit enhanced and refined to take account of more sophisticated user requirements. Velcorin DT Motion, for example, offers a higher degree of automation and digitalization than its predecessor but with zero compromise in safety and reliability. Along with improved software and a more intuitive user interface, various interfaces enable the transfer of data and displays, ensuring that the new generation meets the ever more stringent requirements of Industry 4.0. The equipment has an IoT gateway for data backup, software updates and improved maintenance management – even by remote control.

Among its new, time-saving features are automated preparation for production and constant monitoring and adjustment of the specified dosing rate during the filling process itself. The plug-and-play design of Velcorin DT Motion means that it can be easily integrated in new and existing plants.

Velcorin is used worldwide as a stabilizer across many beverage categories – from fizzy soft drinks, iced tea, juices as well as sport and energy drinks through to mixed beer drinks, cider and wine.

New packaging replaces glass bottles

LANXESS will also be unveiling its latest packaging for Velcorin at Drinktec. The internally coated aluminum bottles specially developed for storing and transporting Velcorin will replace the glass bottles used until now. The new aluminum bottles not only increase the shelf life of Velcorin from 12 to 18 months but are also approved for transportation by air – two key benefits in this age of global logistics bottlenecks.

This new packaging, however, was developed primarily in response to the increasingly widespread no-glass policies enforced by customers in their production areas. In addition, customers can feed these lightweight, break-proof containers back into the material cycles, avoiding the need to collect and return them.

You can find more detailed information about LANXESS products for the beverage industry at www.velcorin.com and www.nagardo.com.

Source and credit