LANXESS presents new sustainable products for the polyurethane industry

- Adiprene LF low-free isocyanate prepolymers enabling superior industrial hygiene

- Energy savings in processing novel hot cast and cold cure systems for high performance elastomers

- Adiprene Green systems with up to almost 90 percent bio-based content reducing product carbon footprint

- Pellart high performance water based lacquers allowing for improved environmental footprint

From October 19 to 26, 2022, specialty chemicals company LANXESS will be showcasing its extensive product range designed to improve sustainability in the polyurethane industry along the value chain at the K 2022 in Duesseldorf, Germany. Visitors will get an insight in a wide range of sustainable products ranging from low free monomer technology (Adiprene LF), innovative Adiprene Green prepolymers with high bio-based content, novel hot cast and cold cure systems for processing with reduced energy consumption, and water based lacquers to meet high requirements of modern and innovative automotive interior.

Benefits for the environment, health and occupational safety

With Adiprene LF, LANXESS offers a wide range of prepolymers with less than 0.1 wt.% free MDI (methylene diphenyl diisocyanate) and other free isocyanates. The range got successfully extended for the use in hot melt adhesives, e.g. in the automotive, construction, electronics and bookbinding industries.

With this low free monomer technology users are protected from potential exposure to free isocyanates, HSE workload is minimized and the handling of materials containing elevated levels of hazardous isocyanates is eliminated. The prepolymers are particularly suited to address increasingly strict regulatory requirements.

LANXESS’ toolbox of low monomer prepolymers is able to tailor the reactivity, viscosity and polyol backbone of the prepolymer to adjust it to the need of the formulators. By controlling the chemical structure, the prepolymers have a highly structured morphology to offer more consistent processing. On curing with chain extenders, their special chemical structure leads to highly structured elastomers with excellent performance.

Adiprene Green – bio-based prepolymers with excellent properties

Like many other industries the urethane industry is facing the challenge to develop sustainable systems with reduced carbon footprint. Under the brand name Adiprene Green LF LANXESS provides a range of bio-based, low free monomer prepolymers for polyurethane CASE (Coatings, Adhesives, Sealants, Elastomers) applications. Bio-based LF prepolymers focus on renewable chemical building blocks that are designed to the specific needs of many different applications by exploring additional chemistries and optimization of molecular weight and structure.

Progress has been made developing bio-based LF MDI prepolymers over a wide range of NCO content (free reactive isocyanate groups) which yield systems with lower viscosity at application temperature, improved high crystallinity, better wetting ability, and fast green strength in reactive hot melt and two-component adhesives formulations. The new LF MDI prepolymers enable hot-melt formulations with a bio-content of up to 75 percent. Other Adiprene Green systems allow the manufacturing of PU elastomers with a bio-content of up to 90 percent.

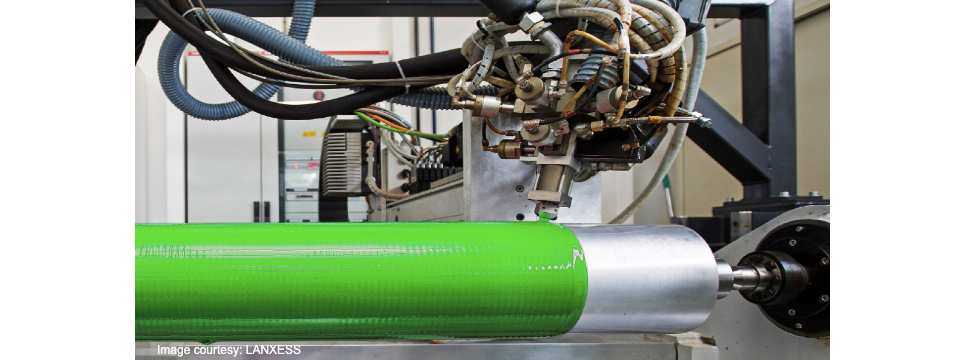

Less energy-intense processing

LANXESS has developed “hot cast and cold cure” systems for high performance PU cast elastomers. While common hot cast systems are cured at elevated temperature, with this new technology, Vibrathane MDI ether prepolymers can be cured with novel Vibracure curatives at ambient temperature. As the systems do not need to be heated during casting process and can be cured at ambient temperature, the specific energy consumption is dramatically reduced down to about 40 percent compared to “hot cure / hot table” technology. Thus, the new technology offers ease of use, energy savings, HSE improvement and, last but not least, a significant reduction of CO2 emissions.

Water-borne systems

Under the newly launched Pellart brand LANXESS offers a range of water based compounds for usage in many functional coatings applications where high requirements in terms of haptics, chemical resistance, gloss level, temperature and abrasion resistance and, above all, the lowest possible content of volatile organic compounds (VOC) are required.

The Pellart compounds are characterized by excellent performance. They are highly suitable for light color designs due to their outstanding yellowing performance, they offer high chemical resistance, allowing cleaning surfaces with alcohol, they show no squeaking, and due to their mechanical performance they can be processed to articles with challenging geometries.

Source and credit