New PET-like plastic made directly from waste biomass

EPFL scientists have developed a brand new, PET-like plastic that's simply constituted of the non-edible components of crops. The plastic is hard, heat-resistant, and a great barrier to gases like oxygen, making it a promising candidate for meals packaging. On account of its construction, the brand new plastic will also be chemically recycled and degrade again to innocent sugars within the atmosphere.

It's becoming more and more apparent that transferring away from fossil fuels and avoiding the buildup of plastics within the atmosphere are key to addressing the problem of local weather change. In that vein, there are appreciable efforts to develop degradable or recyclable polymers constituted of non-edible plant materials known as "lignocellulosic biomass."

After all, producing aggressive biomass-based plastics shouldn't be simple. There's a motive that standard plastics are so widespread, as they mix low value, warmth stability, mechanical energy, processability, and compatibility -- options that any different plastic replacements should match or surpass. And thus far, the duty has been difficult.

Till now, that's. Scientists led by Professor Jeremy Luterbacher at EPFL's Faculty of Primary Sciences have efficiently developed a biomass-derived plastic, much like PET, that meets the factors for changing a number of present plastics, while additionally being extra environmentally pleasant.

"We primarily simply 'cook dinner' wooden or different non-edible plant materials, reminiscent of agricultural wastes, in cheap chemical substances to supply the plastic precursor in a single step," says Luterbacher. "By retaining the sugar construction intact throughout the molecular construction of the plastic, the chemistry is way less complicated than present options."

The method is predicated on a discovery that Luterbacher and his colleagues printed in 2016, the place including an aldehyde may stabilize fractions of plant materials and keep away from their destruction throughout extraction. By repurposing this chemistry, the researchers had been capable of rebuilding a brand new helpful bio-based chemical as a plastic precursor.

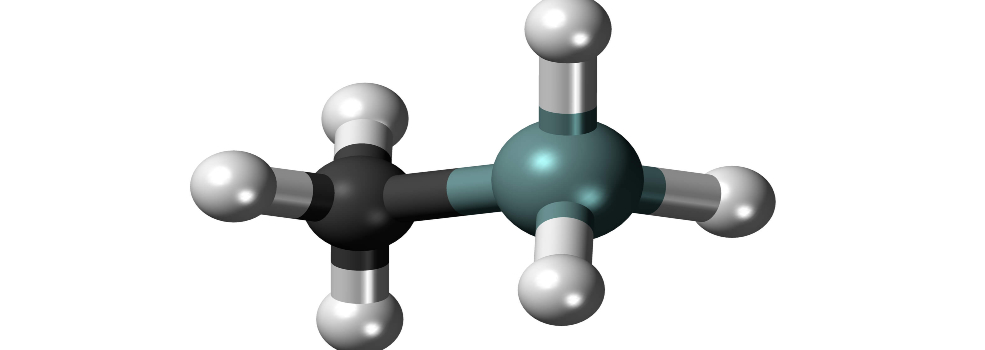

"Through the use of a unique aldehyde -- glyoxylic acid as an alternative of formaldehyde -- we may merely clip 'sticky' teams onto each side of the sugar molecules, which then permits them to behave as plastic constructing blocks," says Lorenz Manker, the research's first creator. "Through the use of this easy method, we're capable of converting as much as 25% of the burden of agricultural waste, or 95% of purified sugar, into plastic."

The well-rounded properties of those plastics may permit them for use in functions starting from packaging and textiles to medication and electronics. The researchers have already made packaging movies, fibers that may very well be spun into clothes or different textiles, and filaments for 3D-printing.

"The plastic has very thrilling properties, notably for functions like meals packaging," says Luterbacher. "And what makes the plastic distinctive is the presence of the intact sugar construction. This makes it extremely simple to make as a result of you do not have to change what nature provides you, and easy to degrade as a result of it may possibly return to a molecule that's already ample in nature."

Story source: Ecole Polytechnique Fédérale de Lausanne.