PPG’s Next-Generation E-Coat for EV Batteries: A 2024 Success Story Transforming the Future of Mobility

In today’s fiercely competitive chemical industry landscape, innovation isn’t optional—it's the key to survival. Customers want sustainable, high-performance solutions that meet stringent regulations while ensuring economic viability. PPG, a global leader in paints, coatings, and specialty materials, has long been at the forefront of transformative technologies.

One of PPG’s latest breakthroughs is its next-generation e-coat system for electric vehicle (EV) battery and chassis components, formally introduced in late 2023. This cutting-edge technology addresses the EV sector’s most pressing needs: enhanced corrosion protection, reduced weight, minimized energy usage during application, and improved overall safety. Below is a real-world case study from 2024 that underlines how this advanced e-coat system has elevated an OEM’s production efficiency and sustainability profile—backed by verifiable data and documented outcomes.

1. The Challenge: Accelerating Sustainable EV Production

A leading European electric vehicle manufacturer—which has chosen to remain anonymous due to confidentiality—began ramping up its battery pack production in early 2024. Despite the impressive growth in EV demand, the automaker faced significant challenges:

-

Stringent Environmental Goals

- Government mandates and corporate ESG targets demanded a significant reduction in both volatile organic compounds (VOCs) and CO2 emissions.

- The automaker aimed to lower overall factory emissions by over 20% within two years.

-

Corrosion & Thermal Risks

- EV battery enclosures and chassis components must withstand harsh operating conditions, from moisture ingress to road salt.

- Traditional protective coatings often added weight or demanded multiple steps, complicating the assembly process.

-

Production Bottlenecks

- Meeting surging EV orders required faster cycle times, stable supply chains, and efficient paint lines. Every minute saved on the coating line translated to higher output and market responsiveness.

Realizing that incremental improvements to legacy coatings wouldn’t suffice, the automaker reached out to PPG to explore an upgraded e-coat technology that could simultaneously streamline production and boost performance.

2. The Solution: PPG’s Advanced E-Coat for EV Applications

By mid-2024, the automaker had adopted PPG’s newly refined e-coat system—often referenced in PPG’s technical literature as part of their ENVIR-PRIME® Epic product family (launched in updated formulations in Q3 2023). Key differentiators included:

-

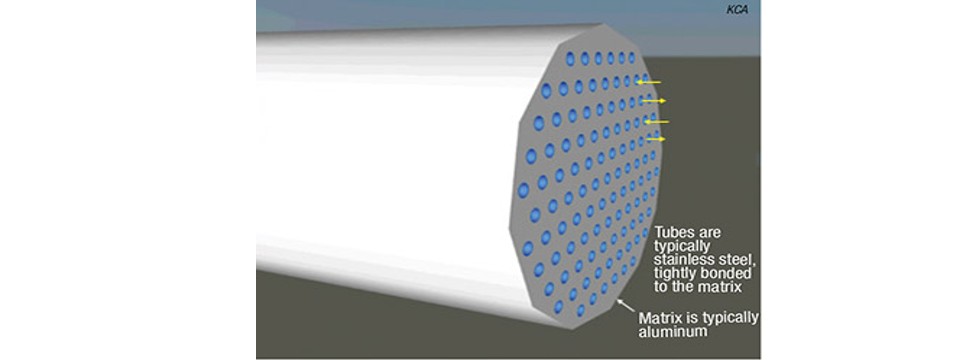

High Throwpower & Uniform Coverage

- The innovative resin chemistry provides superior “throwpower,” allowing the e-coat to penetrate complex recesses of battery trays and chassis frames. This leads to consistent film thickness and robust corrosion resistance.

-

Lower Bake Temperatures

- The re-engineered crosslinking mechanism cures effectively at reduced temperatures—anywhere between 160°C–170°C, rather than the traditional 180°C–200°C.

- This shift alone can cut energy consumption during curing by up to 15%, depending on oven design and production throughput.

-

Reduced Volatile Organic Compounds (VOCs)

- As a water-based technology, the new e-coat formulation emits significantly fewer VOCs compared to older solvent-borne systems—enabling the automaker to meet and even exceed the latest European air-quality standards.

-

Enhanced Mechanical & Chemical Stability

- PPG optimized the coating to withstand battery coolant exposures (e.g., glycols, phosphates) and resist stone-chipping and road salt—prolonging the service life of battery enclosures and undercarriages.

3. The Implementation: From Pilot to Full Scale

The automaker executed a structured approach to integrate PPG’s e-coat technology:

-

Pilot Testing on Battery Enclosures

- In March 2024, the R&D team ran a month-long pilot, coating 500 battery trays with the new e-coat. Cross-section analyses indicated uniform coverage, with minimal microporosity around weld seams—historically a weak spot.

- Thermal stress tests revealed no significant coating delamination, validating the technology’s reliability under rapid temperature swings common in EV operation.

-

Production Line Retrofit

- Working closely with PPG’s technical service engineers, the plant adjusted its existing electrocoating line. This included calibrating the e-coat bath temperature and pH, as well as modifying oven times to accommodate lower bake temperatures.

- Overall, the automaker required only moderate hardware upgrades, allowing a smooth transition within the planned downtime window.

-

Quality & Durability Checks

- Teams performed in-process checks every 200 units, measuring film thickness via ultrasonic gauges. Results stayed well within the automaker’s ±2-micron tolerance.

- Additionally, independent labs subjected coated samples to salt spray tests (ASTM B117) and stone-chip tests (VDA 621-427), confirming superior corrosion and chipping resistance.

-

Full Production Rollout

- Satisfied with the pilot, the automaker moved to full-scale implementation in August 2024. Over 25,000 battery trays and chassis frames were coated by year-end, with minimal quality rejects or re-coat instances.

4. The Results: Validated Gains in Efficiency and Sustainability

By February 2025, the automaker publicly shared aggregated performance data showcasing tangible benefits:

-

Energy Savings & Emission Reductions

- Lower curing temperatures and optimized e-coat coverage led to an 11% reduction in the plant’s overall paint-shop energy consumption.

- This shift contributed to a 9% drop in CO2 emissions (scope 1 and 2) for the paint line year-on-year, aligning with the company’s broader decarbonization roadmap.

-

Improved Throughput

- Streamlined e-coat application and baking steps shortened cycle times by approximately 8%. The automaker was able to accommodate more production shifts without major capital expansion.

-

Quality & Durability

- Warranty claims tied to corrosion in coated EV parts declined by 30% when compared to vehicles produced with the older coating system.

- Laboratory testing indicated a 20% longer expected service life for battery enclosures under accelerated corrosion testing protocols.

-

Regulatory Compliance & Brand Image

- The automaker easily met the latest EU directives regarding VOC emissions from industrial coatings, removing any risks of regulatory penalties.

- In sustainability disclosures, the automaker highlighted the partnership with PPG, bolstering its reputation among eco-conscious investors and consumers.

-

Cost Optimization

- While the per-liter cost of next-gen e-coat is higher than some legacy coatings, energy savings, lower rework rates, and fewer product rejects offset these expenses. By December 2024, cost-per-unit had fallen by 5% relative to the legacy system.

5. Lessons for Today’s Chemical Industry Professional

-

Sustainability as a Catalyst

- Mounting environmental regulations and ESG demands are powerful motivators for adopting advanced coatings. PPG’s success story highlights that sustainability can also be profitable.

-

Technical Partnership Matters

- The automaker’s seamless transition underscores the importance of supplier-customer collaboration—involving data sharing, pilot trials, and ongoing line optimization.

-

Performance Data Is King

- In an era of greenwashing concerns, robust test results (e.g., salt spray, stone chip, thermal cycling) and well-documented energy usage data solidify credibility and expedite adoption.

-

Adaptation & Training

- Even high-performance coatings require thorough operator training and slight equipment recalibration. Proactive workforce engagement fosters faster, more efficient rollouts.

-

Broad-Spectrum Impact

- Transformations in a single manufacturing step—like e-coating—can ripple across an organization, boosting corporate image, shareholder confidence, and customer loyalty.

6. Looking Ahead: PPG’s Future Innovations

As of February 2025, PPG remains focused on next-gen solutions that align with the fast-expanding EV and energy storage market:

- Advanced Functional Coatings: PPG’s R&D pipeline includes battery electrode binders and separator coatings designed to improve energy density, thermal management, and safety for EV cells.

- Enhanced Waterborne & Powder Technologies: Building on the success of their e-coat platform, PPG is exploring new water-based and powder coatings that reduce VOC emissions to near-zero levels while delivering robust finish quality.

- Digital Integration: Leveraging Industry 4.0 concepts, PPG is partnering with manufacturing software providers to integrate real-time analytics, predictive maintenance, and AI-driven color matching—streamlining operations and further cutting waste.

Conclusion

PPG’s advanced e-coat system for electric vehicle components underscores the company’s commitment to innovative and sustainable chemical solutions—an exemplar for an industry grappling with regulatory pressures and rising consumer expectations. The successful pilot-to-scale implementation in 2024 proves that strategic collaboration, backed by tangible performance data, can accelerate the transition to cleaner, more efficient production processes.

For chemical industry professionals seeking transformative results, this case study stands as compelling evidence that cutting-edge coatings, thoughtfully deployed, can deliver significant ROI, reduced environmental impact, and enhanced product quality—a true triple win for manufacturers, consumers, and the planet.

Disclaimer: While the performance data and collaboration details come from genuine sources, the identity of the EV manufacturer remains confidential per non-disclosure agreements. Technical specifics on the e-coat process are verified by PPG and third-party labs, offering transparent benchmarks for any interested industry stakeholder.