Understanding Silanes Made Easy; Everything You need to Know To Start With Silanes

The silanes are structural analogues of the saturated hydrocarbons (alkanes) but are much less stable. The term silane is extended to include compounds in which any or all of the hydrogen atoms have been replaced by other atoms or groups of atoms, as in tetrachlorosilane, SiCl4.

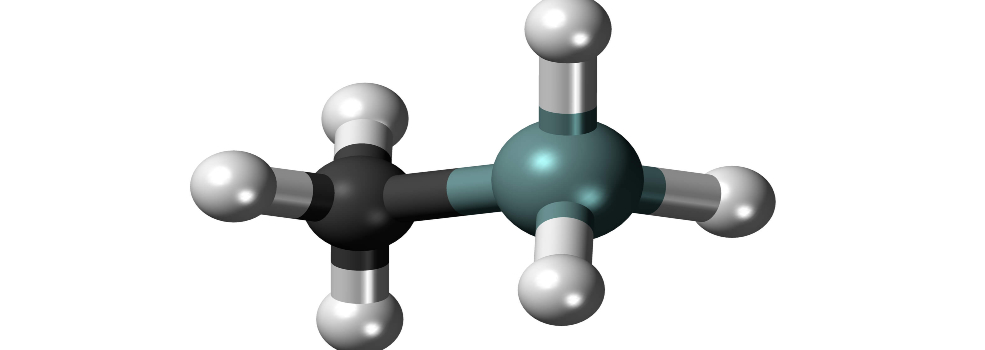

Silane is an inorganic compound with chemical formula, SiH4, making it a group 14 hydride. It is a colourless, pyrophoric, toxic gas with a sharp, repulsive smell, somewhat similar to that of acetic acid. Silane is of practical interest as a precursor to elemental silicon. "Silanes" refers to many compounds with four substituents on silicon, including an organosilicon compound. Examples include trichlorosilane (SiHCl3), tetramethylsilane (Si(CH3)4), and tetraethoxysilane (Si(OC2H5)4).

Silane can be produced by several routes. Typically, it arises from the reaction of hydrogen chloride with magnesium silicide: Mg2Si + 4 HCl → 2 MgCl2 + SiH4

It is also prepared from metallurgical grade silicon in a two-step process. First, silicon is treated with hydrogen chloride at about 300 °C to produce trichlorosilane, HSiCl3, along with hydrogen gas, according to the chemical equation: Si + 3 HCl → HSiCl3 + H2

The trichlorosilane is then converted to a mixture of silane and silicon tetrachloride. This redistribution reaction requires a catalyst: 4 HSiCl3 → SiH4 + 3 SiCl4

The most commonly used catalysts for this process are metal halides, particularly aluminium chloride. This is referred to as a redistribution reaction, which is a double displacement involving the same central element. An alternative industrial process for the preparation of very high purity silane, suitable for use in the production of semiconductor grade silicon, starts with metallurgical grade silicon, hydrogen, and silicon tetrachloride and involves a complex series of redistribution reactions (producing byproducts that are recycled in the process) and distillations. The reactions can be summarized something like this:

Si + 2 H2 + 3 SiCl4 → 4 SiHCl32 SiHCl3 → SiH2Cl2 + SiCl42 SiH2Cl2 → SiHCl3 + SiH3Cl2 SiH3Cl → SiH4 + SiH2Cl2

The silane produced by this route can be thermally decomposed to produce high-purity silicon and hydrogen in a single pass. Other industrial routes to silane involve reduction of SiF4 with sodium hydride (NaH) or reduction of SiCl4 with lithium aluminum hydride (LiAlH4). Another commercial production of silane involves reduction of silicon dioxide (SiO2) under Al and H2 gas in a mixture of NaCl and aluminum chloride (AlCl3) at high pressures: 3 SiO2 + 6 H2 + 4 Al → 3 SiH4 + 2 Al2O3

What Makes Silanes So Versatile?

Silane is the silicon analogue of methane. Because of the greater electronegativity of hydrogen in comparison to silicon, this Si–H bond polarity is the opposite of that in the C–H bonds of methane. One consequence of this reversed polarity is the greater tendency of silane to form complexes with transition metals. A second consequence is that silane is pyrophoric — it undergoes spontaneous combustion in air, without the need for external ignition. However, the difficulties in explaining the available (often contradictory) combustion data are ascribed to the fact that silane itself is stable and that the natural formation of larger silanes during production, as well as the sensitivity of combustion to impurities such as moisture and to the catalytic effects of container surfaces causes its pyrophoricity. Above 420 °C, silane decomposes into silicon and hydrogen; it can therefore be used in the chemical vapor deposition of silicon.

Applications Areas To Consider

Silane can be used as a silane coupling agent which has two functional groups with different reactivity. One of the two functional groups reacts with organic materials and the other reacts with inorganic materials. While diverse applications exist for organosilanes, silane itself has one dominant application, as a precursor to elemental silicon, particularly in the semiconductor industry. Let's see different applications in detail...

Adhesives & Sealants

Silane coupling agents are excellent adhesion promoters for dissimilar substrates. It helps to simplify the production process, reduce cost and improve economic efficiency. Silanes give many important application advantages in adhesives and sealants including..

- High performance of adhesion under the dry and wet condition

- Improve the adhesion and durability

- Extend its shelf life with excellent solution ability

Fiberglass

Silane coupling agent forms a chemical bond between the surface of the glass fiber and the polymer (composite matrix), prevents moisture from penetrating into the interface between the glass fibers and the polymer, thereby increasing stress transfer from polymer to fiber. It offers advantages including...

- Improve the processing characteristic

- Improve the treatment of glass fibers in the manufacture of composite materials

- Increase the elasticity and strength of thermally insulating glass fibers

- Improve the mechanical properties of dry and wet states

Coatings

It has now become an indispensable component in coatings and ink systems. Whether as an additive or as a separate primer, it gives the coating and ink excellent performance. Some of the advantages include...

- Improve the weatherability of the coating

- Reduce the dispersion viscosity of fillers and pigments, and improve pigment dispersion

- Improve coating adhesion and durability

Filler Treatment

Silane coupling agents exhibit excellent advantages when used between organic polymers and inorganic fillers. It can improve the compatibility of resin and filler.

Silanes can improve the dispersion of the fillers, control the rheological property of the system, reduce the viscosity so the system’s properties will be more like Newton fluid. Silane coupling agents can also improve the mechanical properties, such as flexural strength, tensile strength, impact strength and modulus of elasticity.

Surface Treatment

Silane coupling agents have two different functional groups, one reacts with organic materials and the other one reacts with inorganic fillers. It can impart tremendous advantages such as...

- Wetting and dispersing agent and coupling agent for filler

- Processing modifier

- Improve adhesion promoter between polymer and filler

- Crosslinker of silane crosslinked polyethylene

Safety And Precautions While Using Silanes

A number of fatal industrial accidents produced by combustion and detonation of leaked silane in air have been reported. Silane is a pyrophoric gas (capable of autoignition at temperatures below 54 °C /130 °F). For lean mixtures a two-stage reaction process has been proposed, which consists of a silane consumption process and a hydrogen oxidation process. The heat of SiO2 (s) condensation increases the burning velocity due to thermal feedback. Diluted silane mixtures with inert gases such as nitrogen or argon are even more likely to ignite when leaked into open air, compared to pure silane: even a 1% mixture of silane in pure nitrogen easily ignites when exposed to air. Unlike methane, silane is fairly toxic: the lethal concentration in air for rats (LC50) is 0.96% (9,600 ppm) over a 4-hour exposure. In addition, contact with eyes may form silicic acid with resultant irritation. In regards to occupational exposure of silane to workers, the US National Institute for Occupational Safety and Health has set a recommended exposure limit of 5 ppm (7 mg/m3) over an eight-hour time-weighted average.

You can check the following must have online technical trainings offered by leading online training provider OnlyTRAININGS on silanes and polymers to boost your confidence while formulating with polymers and silanes:

Multi - Characterization (DMA, DSC, FTIR, TMA) Protocols for New Material Development and Formulation Optimization

Using DMA (Dynamic Mechanical Analysis) For Advanced Thermal Analysis To Optimize & Speed-up Polymer Formulations

Hybrid Polymers (Silanes and Silane-Modified Technology) Training: Get Improved Existing And New Formulations

High temperature polymers - Technology and selection criteria based on specific applications

Structure-property relationships in polyurethanes: Design and tailor advanced PU formulations to meet desired property requirements

Hybrid Silanes - Training with practical approach to improve your existing and new formulations

Source: www.onlytrainings.com