Solvay marks milestone in digital mining journey with SmartFloat™, a solution for more efficient and sustainable base metal flotation

Industry-first, AI-based reagent optimization system helps mining companies capture more value from their data and optimize froth flotation processes.

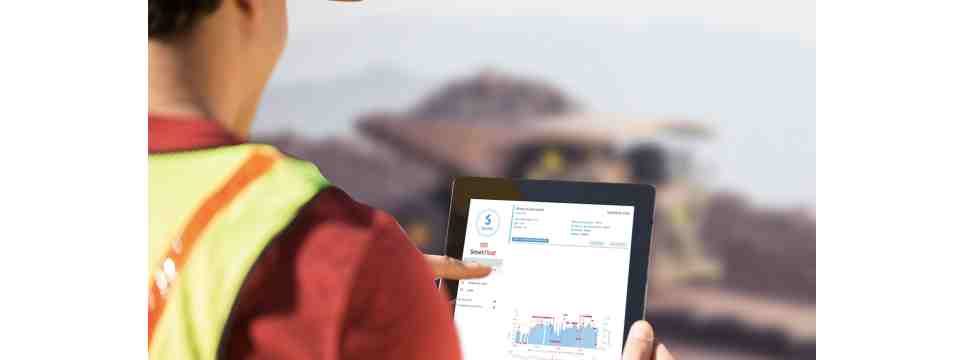

Solvay, a global market leader in mining reagent-based solutions for more than 100 years, is continuing its digital journey with SmartFloat™, which is a first-of-its-kind digital system based on artificial intelligence (AI) that enhances base metal flotation by improving operational efficiency, metallurgical results and sustainability. SmartFloat™ provides another tool for flotation operations to implement improvements, just as SolvExtract® has done for solvent extraction since its launch in 2019.

Bringing Solvay’s expertise to customers’ fingertips, SmartFloat™ helps mining operators automate tasks, streamline decision making processes and optimize grade and/or recovery. “Miners worldwide are facing increased ore variability at lower grades and request more automation,” said Nicolas Renaud, Digital Business Transformation Director at Solvay. “Digital solutions can address these challenges, but are often met with reservation as to their utility and use in the rugged environment of mineral beneficiation. SmartFloat™ provides a user-friendly and mining-focused interface to maximize the stability and control of the beneficiation process.”

Building on Solvay’s proprietary Flotation Matrix 100TM approach, SmartFloat™ uses live flotation data to recommend the best suitable reagent formulation and dosage in real time, based on incoming ore properties and operational parameters. SmartFloat™ enables operators to respond faster to changes in ore composition, helping avoid loss of valuable metals and save energy, while reducing reagent consumption and cost. Moreover, the system can be tailored to specific customer process needs.

SmartFloat™ is a perfect complement to the Solvay Cube, a state-of-the-art dosing system that enables more precise blending and dosing control of reagent building-block chemicals. The data and insights gathered by SmartFloat™, together with the Cube’s formulation capabilities, can be used to automate reagent injection into the flotation cell.

Several operations worldwide are currently implementing SmartFloat™ for their copper and copper-gold ore processing operations.

SmartFloat™ is a trademark of Solvay.